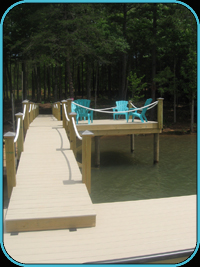

Gray's Project

New Pier, Seating Area, Ramp, Floating Slip, and Installation of River Rock

* Pilings: Marine grade wood pilings were driven into the lake bed to support the frame of the pier, ramp, and seating area. Pilings were installed inside the floating slip to accommodate a future boat lift installation. Also X bracing is installed where needed.

* Frame: 2 x 8 pressure treated lumber fastened together with galvanized rust resistant bolts.

* Frame Encasements: Pressure treated 2 x 10 lumber was through bolted to the side of the ramp frame with galvenized rust resistant bolts. The 2 x 10 lumber encased the frames and created an inset decking effect.

* Floatation: Black Formex floats secured to the frame with galvanized rust resistant bolts.

* Dock Rubbers and Cleats: Black Astro Nautics dock rubbers where nailed to the side of the floating slip frame with black PolyTop nails. Four cleats were bolted to the frame of the floating slip with galvanized bolts and placed on the floating slip deck.

* Decking: Khaki colored Veka decking fastened down with stainless steel decking screws.

* Nautical Rope: 6 x 6 pressure treated post with stainless steel caps were through bolted to the side of the frame on the seating area, pier, and ramp with galvenized bolts. The post had one hole drilled into the top of them so that white braided nautical rope could be threaded through.

* River Rock:Before the River Rock was installed the area where the rocks were placed was cleaned of debris and smooth out. Then there was black landscaping cloth laid on top of the shoreline. Now the area is ready for the River Rock. The thicker rocks are selectively placed on the area closer to the water. All of the rocks are arranged in an attractive manner.